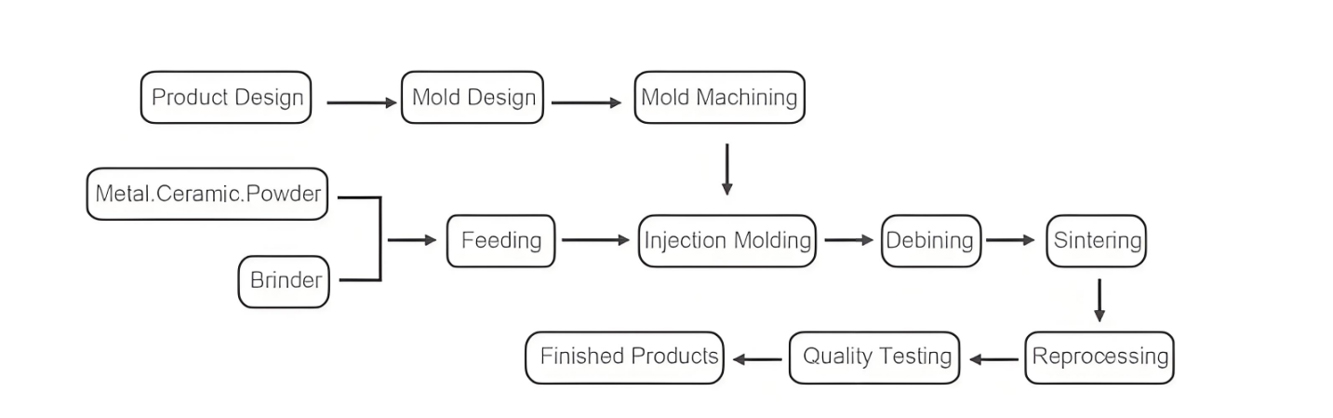

HZMIM's continuous flow manufacturing process has allowed us to achieve efficiencies that we can pass on to our customers throughout the product lifecycle. Flexibility is the cornerstone of our customer-focused supply chain management system, enabling us to meet complex demands.

In Process Control

- All standard alloys plus application-specific materials developed upon request

- Experienced process and metallurgical team

- ISO 9001:2015 registered

- Historical control data saved electronically

- Production associated response

HZMIM provides a flexible customer order process. You just need to contact our service representatives to determine all steps during the R&D and machining processes. The shipping method will be selected according to your requirements. HZMIM's quality assurance and engineering expertise ensure reliable results.

Instrumentation and Test Equipment

- Pin Gauge

- Micrometer

- Microscopy

- Dynamometers

- Hardness Tester

- Torque Rheometer

- Precision Balances

- Impact Test Equipment

- Rijing electric injection machine

- Changfei sub-electric injection machine

- Donghua plastic injection molding machine

- Spire catalytic debonding furnace

- Constant pressure vacuum sintering furnace

- Samuel Noah Kramer continuous atmosphere sintering furnace

- Shaping Press(air pressure)

- LEGO Carbon Analyzers

- Metallographic Equipment

- Mechanical Testing Equipment

- Density measurement equipment

- DCC Coordinate Measuring Machines

- Advanced Surface Characteristic Instruments

- High Precision Length, Parallelism, and Flatness

- Changfei sub-electric injection machine

- Arbogart hydraulic injection machine

- Sea-sky plastic injection molding machine

- Constant pressure vacuum sintering furnace

- Vacuum Sintering Furnace

- Samuel Noah Kramer continuous atmosphere sintering furnace

- Shaping Press(hydraulic)

- Equipment

.png)

.png)