|

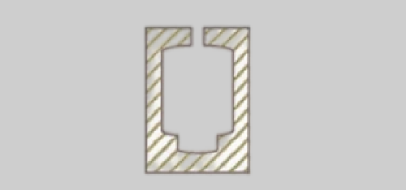

1.Manufacturing of injection mould

Create the original model by casting the parts. The model outlines the casting |

|

|

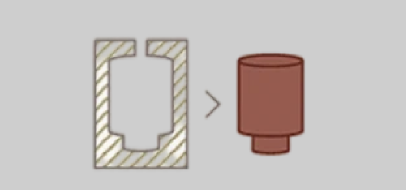

2.Wax injection molding

Pour the wax into the mould and shake it around until the inner surface of the mould is covered with a uniform coating, which requires precise coordination between the injection pressure of the machine and the temperature of the wax to ensure higher dimensional accuracy and surface quality |

|

|

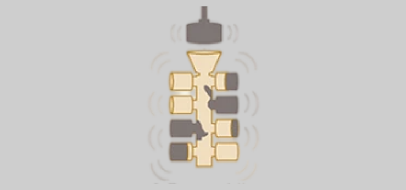

3.Assembly of wax models

Multiple wax moulds can be created and assembled to form a wax tree for casting in a batch casting. Experienced staff carefully assembled to ensure that the casting parts of high quality |

|

|

4.Impregnation, sandblasting, drying

The wax tree is repeatedly dipped into a ceramic sauce, coated with sand and dried to form a ceramic shell |

|

|

5.Dewaxing

After the ceramic mold is fully cured, it is turned over and placed in a furnace or autoclave to melt and/or evaporate |

|

|

6.firing

The die is then burned, heated to between 870 ° C and 1095 ° C to remove any moisture and residual wax, and the die is sintered |

|

|

7.casting

The customer-specific alloy constituents required for each casting batch are compiled and melted in our induction furnace. The molten metal is then poured into the hot ceramic mould using a pouring ladle. The precise temperature control of the molten steel, pouring ladle and ceramic moulds assures the high material quality and surface finish even for thinwalled components with complex geometries. |

|

|

8.Demoulding

Once the cluster has cooled, the ceramic shell is carefully removed. |

|

|

9.separating

The casting is separated from the runner. |

|

|

10.shot blasting

Any ceramic residues are removed from the surface of the castings in a blasting process. Finally, they are polished, heat treated, dressed, machined and/or surface coated as required by the customer. |

|

|

11.final inspection

Optical inspection of 100% of all investment casting products. The full set of standards and measures used in quality control are coordinated with customers according to their specific requirements. |

|