What's Metal Injection Molding?

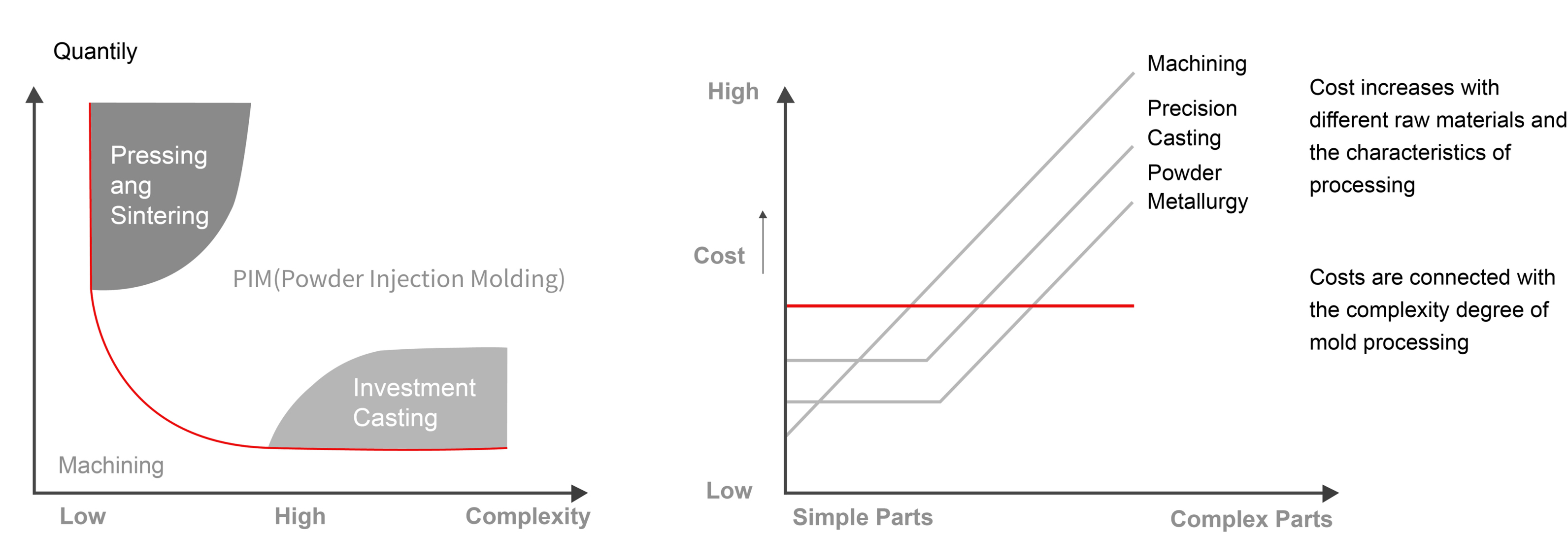

Metal Injection Molding (MIM) combines the technologies of thermoplastic injection molding and powder metallurgy to produce complex-shaped, high density, high performance metal parts.

Best applied to small parts (typically less than 100 grams), the MlM process offers lower cost solutions for numerous applications compared to machining or investment casting, and improved mechanical properties compared to plastic injection molding or zinc die casting.The technology has matured and gained acceptance in numerous industries, including Automotive Systems, Medical and Dental instruments, Orthodontics, Firearms, Hardware and Lock Components, and Computer and Electrical applications.

Key Attributes

• MlM is a repeatable process for complex components made from high temperature alloys.

• MlM parts are near fully dense, which gives excellent mechanical, magnetic, corrosive and hermetic sealing properties, & allows secondary operations like plating, heat treating, & machining to be easily performed.

• The shrinkage from molded parts to sintered parts is high (14-18%) but isotropic & controllable

• Complex shapes are achieved through tooling techniques used in the plastic injection molding industry. High volumes are attained through multi-cavity tooling.

Criteria for Typical MIM Parts

• High melting point alloys (ferrous & higher).

• Complex shapes (can't be stamped, screw machined, made in powder metal, etc.).

• Relatively small components (<100 grams best) due to price of MIM powders & cost of thermal processing.

• Cross-sectional thicknesses of 7 mm or less. MIM tooling can often be designed to reduce cross-sectional thicknesses without sacrificing component performance.

• Part volume high enough to amortize tooling.

• Geometry suitable to be made through standard plastic injection molding tooling.

• Relatively low-cost prototyping available for simple shapes.

MIM and PM Microstruture Comparison

The particle diameter of MIM material powder is from 2 to 15μm instead of from 50 to 100μm in traditional PM material powder, thus the density of MIM products is high. And the flexible shaping of MIM products cannot be achieved through traditional PM.

|

|

|

| PM | MIM |

Comparison between MIM and Traditional Machining

|

Item |

Processing Method |

|||||

|

MIM |

Investment Casting |

Traditional Powder Metallurgy |

Forging |

Machining |

Die-casting |

|

|

Shape Complexity |

4 |

5 |

2 |

2 |

4 |

4 |

|

Design Flexibility |

5 |

3 |

2 |

2 |

4 |

3 |

|

Dimensional Precision |

4 |

3 |

4 |

5 |

5 |

3 |

|

Mechanical Strength |

4 |

4 |

2 |

5 |

5 |

4 |

|

Material Applicability |

5 |

4 |

5 |

2 |

3 |

2 |

|

Tooling Charge |

3 |

4 |

3 |

1 |

5 |

3 |

|

Volume Production |

5 |

2 |

5 |

5 |

3 |

5 |

|

Product Price |

3 |

2 |

4 |

5 |

2 |

4 |